Radiation

SeAH Networks provides high-tech, non-destructive radiographic testing solutions that incorporate various scanning and identification techniques to ensure that clients can detect and remove potential threats before they become a problem.

Container Scanners

Our container scanner technology uses non-destructive radiographic scanners to test and identify the contents of a shipping container safely and securely. We provide state-of-the-art, high-tech solutions with systems that allow us to transport trucks without the involvement of a driver, ensuring that there is no risk of radiation exposure in the pursuit of our mission of strengthening international customs processes, maintaining a safe society, and contributing to the competitive viability of South Korea.

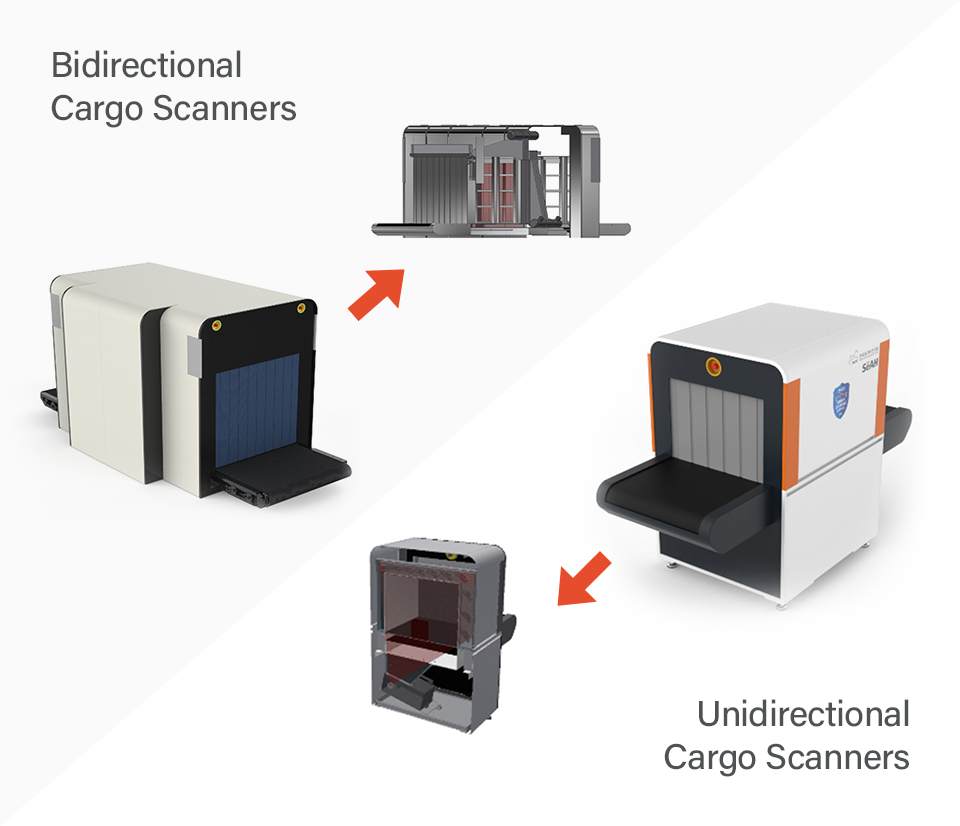

Cargo Scanners

By ensuring quick customs processes for a large number of a wide variety of shipments, developing Korean equipment that implements AI identification technologies, and investing in the development of outstanding technologically independent Korean cargo scanners, SeAH Networks is building the core foundation for a Korea-based global security scanner industry.

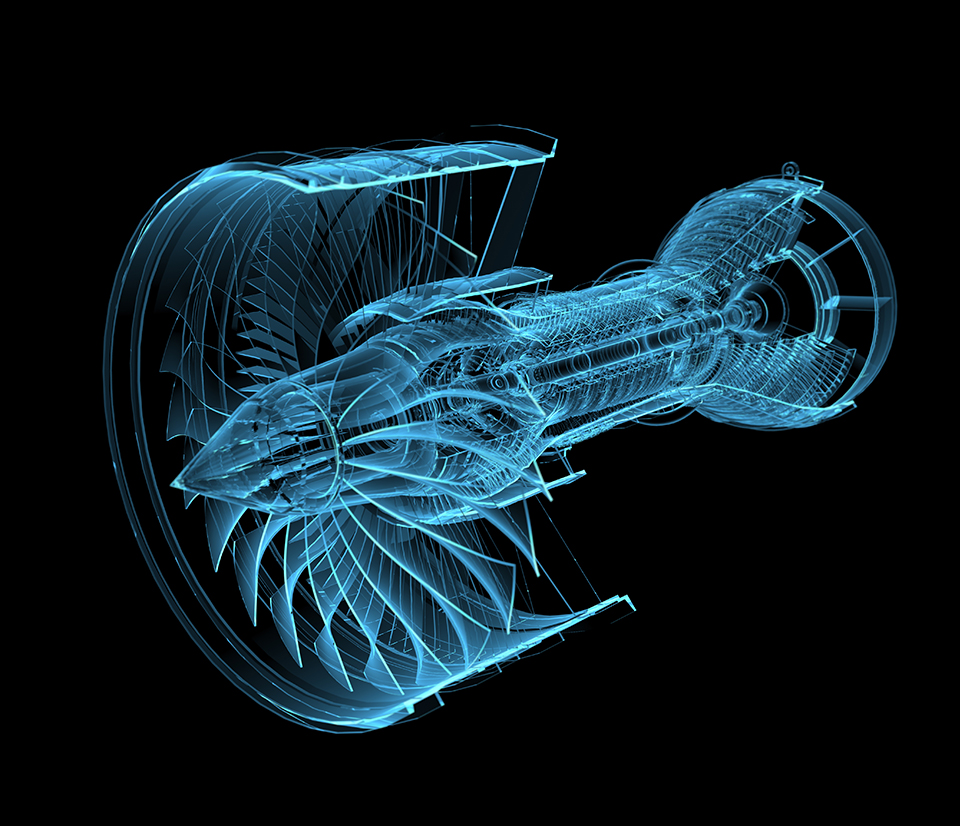

Non-Destructive Testing

Our non-destructive testing methodology uses X-rays to

scan and inspect an object for the purpose of identifying

any holes, cracks, structural defects, impurities or

foreign objects, etc. by using non-destructive testing

techniques based on high-energy, high-penetration

radiography technology to identify and inspect internal

defects without damaging or destroying materials or

structures. We’ve expanded our testing services to a wide

variety of sectors including aerospace, defense

technologies, shipbuilding, automotive production,

construction, steel manufacturing, food products, and

medical equipment, fueling our growth as an

industry-leading company worth over 30 Trillion KRW on the global market.

Using our unparalleled world-class container scanning technology as a foundation, SeAH Networks offers high energy x-ray scanning solutions for the non-destructive testing of objects such as steel products(such as billets, large pipes, metal structures, and forged parts), defense technologies(such as in comprehensive missile testing), and cultural heritage artifacts and structures, in partnership with KAERI, defense contractors, heavy industry firms, and national museums, as an industry-leading provider of testing solutions both domestically and abroad.